Although there are a number of technical parameters to evaluate the quality of any PV Modules, the Fill Factor is the quickest way for knowing the quality/grade of a particular PV Module. FF is not indicated by manufacturers on the datasheet. That is for a reason. Because when you seek that information, your manufacturer would know that they can’t give you modules based on lower fill factor.

In my personal experience, the TUV and other certifications against IEC Standards are depicted from the actual test report generated on a calibrated and traceable Sun Simulator. The professional Solar Power designers quickly assess the quality of a PV module by knowing the Fill Factor (FF). The Fill Factor is the ratio of the maximum power to the theoretical power that would be simulated as the output at both the circuit voltage and short circuit current together. Excellent solar panels have FF greater than 80%.

Try Fill Factor to Select PV Modules

The learned and experienced designers use Fill Factor, more commonly known by its abbreviation “FF” for selecting a PV Module. The Fill Factor is essentially a measure of the quality of a PV module, the theoretical maximum value depending on factors such as the type of silicon used to construct the module and how close the cell is laminated on the module.

The FF is a parameter that, in conjunction with Open Circuit Voltage (Voc) and Short Circuit Current (Isc), determines the maximum power from a solar module. In short, FF is the ratio of the capacity of a module to the product of Open Circuit Voltage (Voc) and Short Circuit Current (Isc); FF= Wp/Voc X Iec. Usually, it is given in percentage by multiplying the value by 100 which is FF%.

Comparison of Some Popular Brands 605 Watt Mono Crystalline PV Modules:

Comparison of Some Popular 300 watt Polycrystalline PV Modules:

The comparisons above are self-explanatory. The efficiency alone is not indicative of the good Quality of a Brand or increased yield of energy there off. Where a true picture comes from the Fill Factor of a module.

Together Efficiency and Fill Factor can be assessed to final select keeping an eye on the price per watt as a critical factor.

[GUIDE] How to Select Solar Panels in Pakistan?In my opinion, if I am going to order PV modules from the above five brands then Leapton Solar a Japanese Brand would be my first choice.

The price per watt is also better for Leapton Solar with lightweight in the same frame of 1.303 m X 2.384 m and extended product warranty up to 15 years have low degradation plus dual insurance from leading Chines and Japanese insurance companies.

Also, You may like to visit the Web site of Sun Solar USA for Mono or Poly in a particular environment.

I do not recommend any brand.

In my experience, local modules made by Tesla Solar Islamabad have also proven good. We have used their mono at remote sites of eight districts of Baluchistan, performing excellently.

This company has a 4th generation automatic cell soldering plant using the infrared heating technique. The damage or discord rate is less than 0.1 % compared with 3rd generation machines of 3% rate. Another reason is that you never know when a Chinese company will stop working and what will happen to the warranty but you are safe if you select a local reliable manufacturer.

Typical FF range from 0.5 to 0.82 and it is also represented as a percentage (Range: FF 50 % to FF 82 %). Higher the Fill Factors, excellent should be the quality or grade of the PV Modules and lower Fill Factors means the bad quality or low grade of PV Modules.

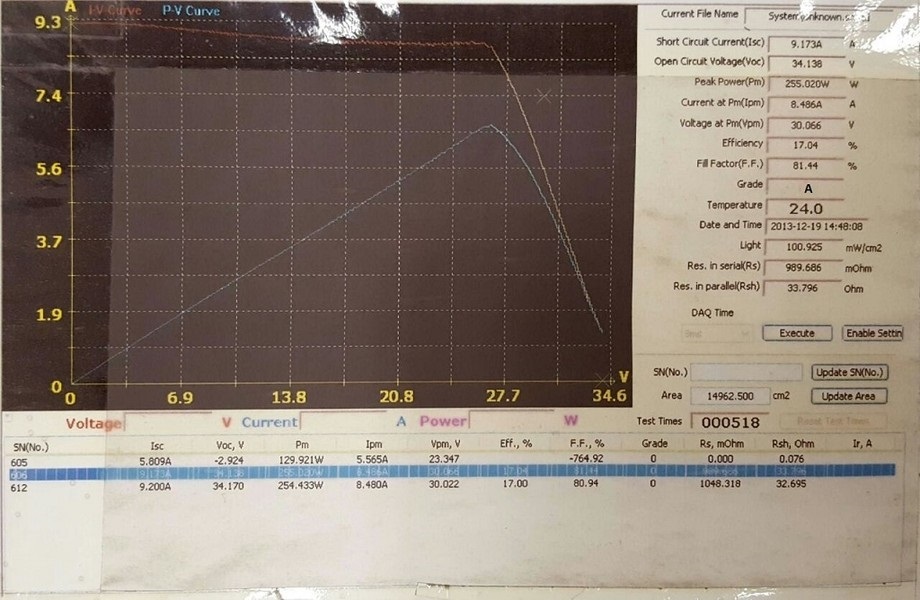

The above test report shows 81.44 % Fill Factor in the PV Modules tested on a Sun Simulator at Standard Test Conditions. Such modules carry excellent quality and fall in the Grade-A category. The professionals can directly select such modules for the reliable design of solar power generation plants.

Tier-1 manufacturers share this very important parameter on their technical specification sheets. Most of the manufacturers do not share FF, intentionally, because professional designers can quickly judge the quality of their products.

For the interest of readers the other parameters are also visible in the picture of I-V Curves (Current-Voltage Curves) including:

Efficiency of the same module (Eta = 17.04 %),

Short Circuit Current (Isc = 9.173 A),

Open Circuit Voltage (Voc = 34.138 V),

Peak Power (Pm = 255.05 Watt),

Current at Peak Power (Ipm = 8.486 A),

Voltage at Peak Power (Vpm = 30.066 V),

Resistance (of 60 Cells) in Serial (Rs =989.686 milii Ohm).

Cells Resistance (of 60 Cells) in Parallel (Rsh = 33.796 Ohm)

Area of PV Module: 15962.5 cm2

Date and Time of Test Executed : 19th December 2013 at 1448 Hrs,

Note: Standards Testing Conditions (STC) Requirements of International Electrotechnical Commission, IEC 61215 for Testing a Module in a Laboratory:

(N.B: This is one of the IEC Standards against which TUV and UL etc issue certifications)

i. Ambient Temperature at the Time of Testing = 25 Degree Centigrade

ii. Light Radiation = 100 mW/cm^2 (1000 Watt/ m^2)

Note: Actual Testing Conditions of Laboratory maintained during above Test:

i. Ambient Temperature at the Time of Testing = 24 Degree Centigrade

ii. Light Radiation = 100.925 mW/cm2 (1000 Watt/m^2)

iii. Classification = Grade- A

iii. Sun-Simulator used for Flash Test = Solar Module GSMT-H-3A having I-V (Current – Voltage) Test Repeatability = 0.5 %

iii. Sun Simulator Non-uniformity Measurement = 1.82% and Spectrum Match against IEC60904-2007,AM1.5G A standard curve = 0.41 %

Test Conducted by: Khalid Islam

Lesson to learn: Always ask your supplier to furnish the Flash Test Data generated on a Calibrated and Traceable Sun Simulator. The Test Report carries strong evidence of quality rather than 3rd Party Certifications.

One Question for readers:

Three Bus Bar (3 BB) Photovoltaic Cells used are 156 mm X 156 mm (6 inch X 6 inch) and 200 micro thickness made by MARS ROCK, Company, China with stated 18.4 % Efficiency (Eta). (Note: As a thumb rule the Efficiency of the PV Module would be always less than the Efficiency of the PV Cells used. Utmost 1.5 % efficiency is lost that of PV Cells’ efficiency if complete lamination process of module undergoes through tight quality workmanship (see Eta of PV Cells = 18.4 % and Eta of PV Module = 17.04 % in our example).

Question: What type of PV Cells are used with Eta = 18.4 %, choose one: Poly Crystalline or Mono Crystalline?

Disclaimer: The author congratulates you to have made it this far. This is only a reflective study. We conducted a survey among 153 participants (retailers, manufacturers, traders, installers, technicians, business owners, teachers, students, researchers, and consumers) to describe the fill factor. While only 27 participants attempted to describe the concept, an astonishingly high percentage of people (as high as 74 percent) failed to recognize the basic electric current principle.